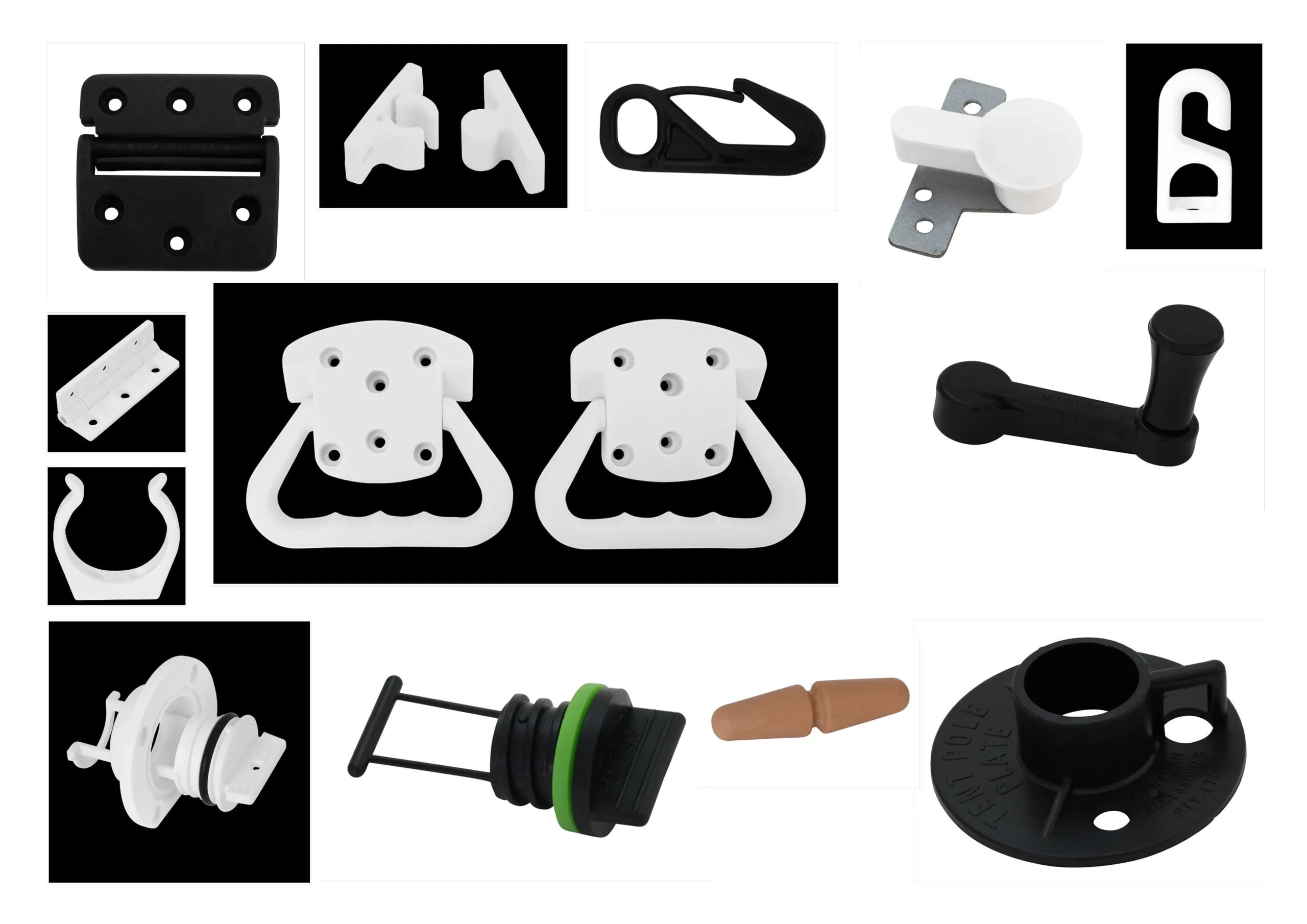

Explore durable tube clip holders for sale at Mardon Australia. Ideal for boating and outdoor use, made from strong Nylon for secure, lasting performance.

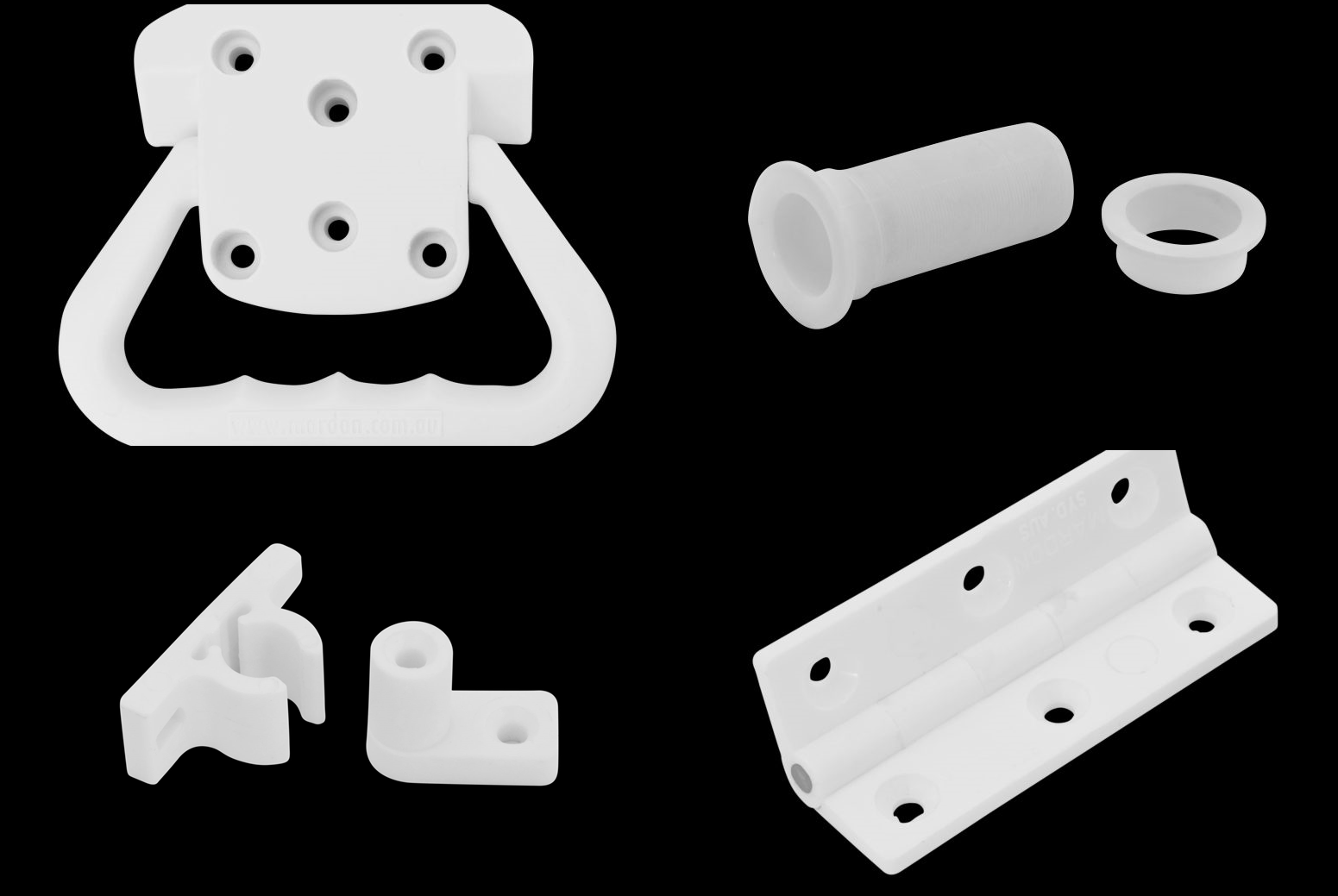

In marine and outdoor environments, durability, functionality, and space-saving solutions are essential. Tube clip holders, also referred to as tube clips or fasteners, are designed to meet these demands efficiently. These practical components are widely used for securing tubular items, particularly on boats, caravans, and outdoor storage setups.

At Mardon Australia, we offer tube clip holders for sale made from robust Nylon 6, engineered to withstand the demands of harsh outdoor conditions. Their reliable construction and versatile design make them a popular choice for a range of applications, from boating to cable management.

Available in 8 Versatile Sizes: A Solution for Every Need

Mardon’s tube clip holders are available in eight size variants, offering flexible options for various fastening requirements. Whether securing thin cables or large tubular equipment, users can select the appropriate size to ensure a secure and stable fit. Each clip is designed for optimal performance in outdoor and marine environments, combining ease of installation with reliable strength.

Available sizes include:

• 13mm Tube Clip Holder

• 16mm Tube Clip Holder

• 19mm Tube Clip Holder

• 22mm Tube Clip Holder

• 25mm Tube Clip Holder

• 32mm Tube Clip Holder

• 38mm Tube Clip Holder

• 44mm Tube Clip Holder

With this comprehensive range, users can confidently choose a clip holder that meets the specific diameter of the item they need to secure.

3 Common Uses of Tube Clip Holders for Boating and Outdoor Applications

1. Storage of Tubular Items on Boats: One of the primary applications of tube clip holders is the storage of tubular items on boats. Space is often limited in marine environments, making efficient storage solutions essential. Tube clip holders provide a secure method for mounting items such as oars, brooms, and fishing rods against walls or under seats, keeping them organised and preventing unwanted movement while the vessel is in motion.

2. Cable Management in Marine and Outdoor Setups: Tube clip holders are also highly effective in managing and organising cables in both marine and outdoor settings. On boats, where electrical and communication systems are often exposed to movement and moisture, keeping cables tidy and protected is crucial. These nylon fasteners provide a structured way to bundle and secure cables, reducing the risk of damage, tangling, or accidents.

3. Use in Caravans and Outdoor Storage: Beyond boating, tube clip holders are widely used in caravans, sheds, and other outdoor environments. Their strong grip and weather-resistant construction make them ideal for mounting tools, garden equipment, and hoses. Whether for permanent installations or seasonal adjustments, these holders help users maintain a neat and efficient storage system in a variety of outdoor settings.

Durable and Versatile Tube Clip Holders for Sale at Mardon Australia

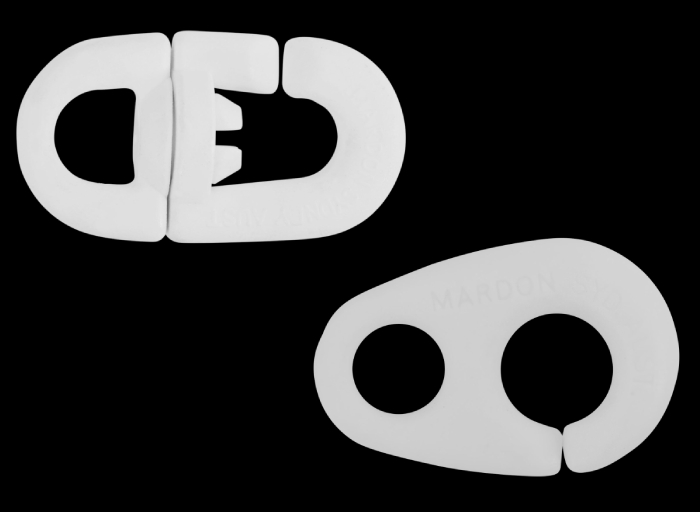

Mardon Australia offers a reliable selection of tube clip holders for sale, specifically designed for marine and outdoor use. As a leading Australian manufacturer of injection moulded plastics, we provide both Mardon-branded and custom products for local and global markets. Made from durable Nylon 6, our tube clip holders deliver long-lasting performance and versatility across a range of applications.

Explore our online shop to find the ideal product for your needs. With a reputation for excellence and reliability, Mardon Australia remains your premier partner for all your boating plastic requirements.